1795.20 (Inc VAT)

Plasma machines with outstanding cutting & gouging performance + metal marking & heating.

Built in CNC interface circuit.

Up to 30mm sever cut, clean cut to 18mm

Information on our inverter technology

For the last 30+ years our Electronic Engineers have repaired almost every fault going on all makes & models, Esab, Miller, Lincoln, EWM, Lorch, Migatronic, CEA, Cebora, GYS, Fronius, Stel, Kemppi, Jasic, OTC, Panasonic etc. Welding & plasma equipment is never used in perfect conditions, damp & dirty workshops are the norm! This alone causes many of the problems. We have seen almost every fault possible; we know what works well & lasts well. We have applied that expertise into these models to give you something different from competitors products. Firstly, we keep things simple. No microprocessor or complex circuitry is fitted. A cooling chamber is used to prevent ingress of debris to the electronics. We don’t parallel 20 or 30 transistors we fit only 2 IGBT modules – minimum parts & maximum reliability! We make everything we can ‘in house’ including inverter transformers, coils & PCBs, we even draw our own copper litz wire. From a serviceability point our inverter machines are simple, no need for an Electronic degree! We include diagnostic LEDs & test points, all OXFORD machines can be maintained by any competent Technician anywhere in the world. CUTMAKER models have protection from damp & dust, they can be operated in harsh conditions indoors or outside, happy to work hard every day or sit in an old workshop for years. They all have ‘fan on demand’ so the cooling fan only runs as needed. All CUTMAKER models have a high duty cycle, 100% ratings are at higher amperages than previous models & max output is up to 60%, perfect for heavy duty jobs & automated work.

Further information on functions & features

All models have a bright digital display which allows you to precisely set the output power before use, press the select switch & the display shows air pressure, the panel mounted air regulator can be precisely set according to your use. A built in 20 micron air filter is fitted to help clean up dirty/damp compressed air. All models have CNC interface circuits built in, just add the 14 pin CPC connector & you can use with automation, cutting tables, robot, etc. without compromising manual use. Move between automatic & manual operation in a minute or so. Two modes of arc operation can be selected, normal & rapid restart (RR). Normal mode allows smooth transfer from pilot arc to transferred arc, with automatic shut down of the arc at the end of a cut or operation. This is used for most cutting & gouging applications both manual & automated. RR mode (rapid restart) works exactly the same as normal at the arc start & transfer, but in the event of arc dropping out such as when cutting discontinuous metal the arc automatically restarts in around a second. This mode may be used for any application such as grill & mesh cutting, intermittent gouging, intermittent metal marking etc.

Cutting performance

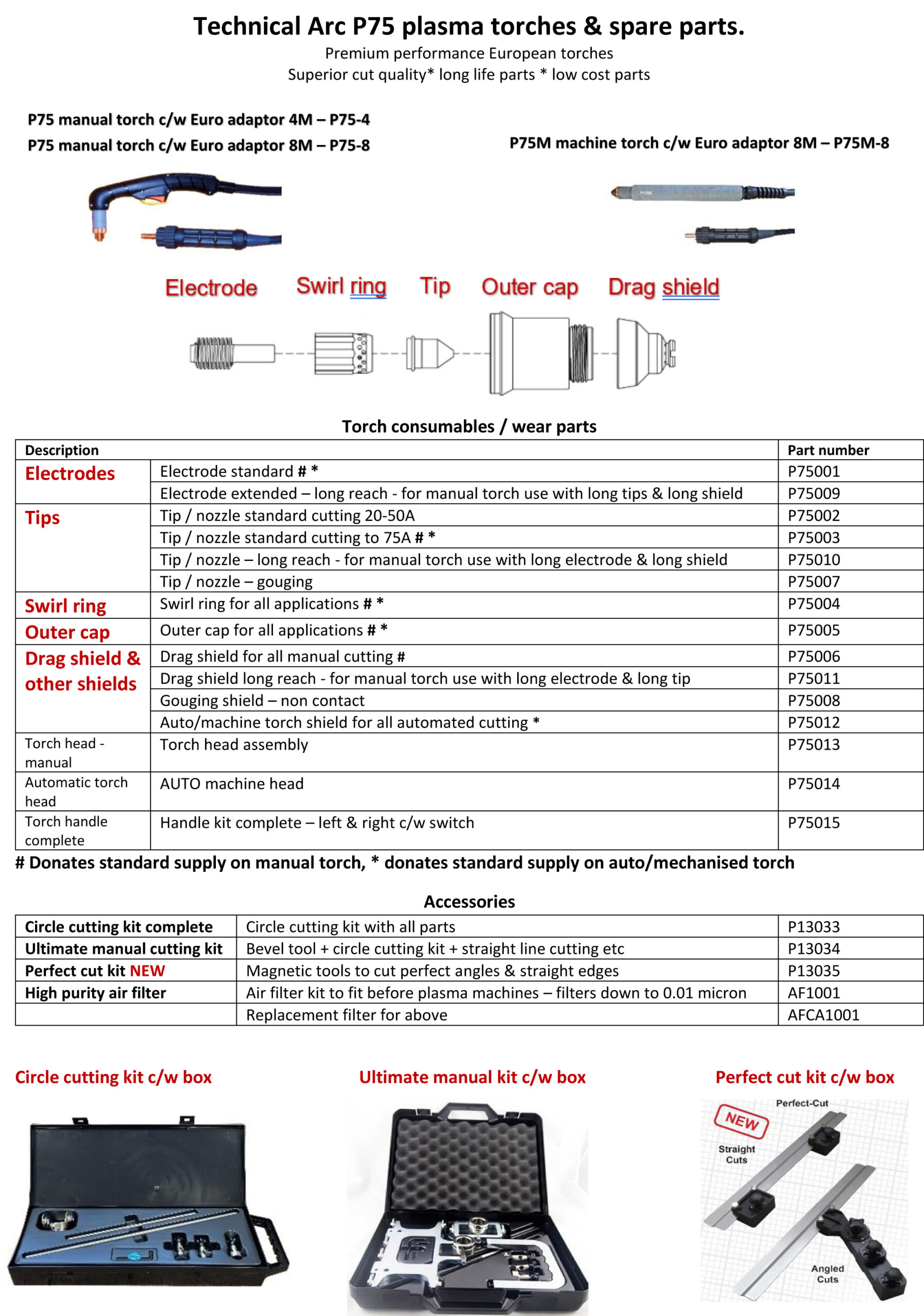

CUTMAKER models offer exceptional cutting performance on all metals. Our design gives a tightly constricted arc minimising kerf width & maximising cut capacity & speed. This results in a very straight clean cut with minimal dross. Even on thick materials such as 30 or 40mm the cut will be clean & close to perfectly straight. Compared with a low cost imported plasmas the performance difference is almost unbelievable. Compared to using oxy-fuel (gas bottles) cutting speed can be more than 5 times as fast & operating costs coming out at around 90% reduced, you also get a better cut quality. Drag cutting parts are fitted to all hand torches, drag cutting is the easiest & neatest option for hand plasma, it gives better access than other plasma torch designs & allows you to follow straight edges or templates with ease. In addition, a range of extended consumables are available for getting into those tight tricky jobs. For cutting below 50A its also possible to carry out tip contact cutting, dragging the cutting tip directly on the job gives even more precision & visual access to the cutting point. CUTMAKER models can also cut the very thinnest of metals with absolute precision, smaller models using the P75 torch work especially well from 0.5mm upwards. Models fitted with the P130 can use the optional ‘fine cut’ consumables to give similar results. Mechanised cutting performance is exceptional, just plug in our P75M or P130M machine torch & fit the CPC connector then you are ready to use on cutting tables, straight line cutters, robot etc. CNC interface uses the same wiring as US made machines, start signal, OK to move contact & we also have adjustable divided arc volts. This can be set to give 20:1, 30:1, 40:1, 50:1 & anything in- between. This gives compatibility with all known cutting tables & THC systems.

Thermal gouging

These models all give great gouging performance from small light jobs right up to the heaviest plate. The arc stretch is unbeatable giving you smoother finishes & better control. Remove welds, wear plates, create weld preps, etc. Can also be used for automated gouging with robots or Gullco carriages & tractors. For gouging use simply replace the tip & shield for gouge parts & reduce air pressure by around 1 bar.

Metal marking

Our metal marking function allows fast clean marking of metals for both automated & manual use. Mark drill points, fold marks, add your logo, date code, ID, etc. Unlike competitors’ products we use standard cut consumables, so move from cutting to marking in a second!

Thermal heating

A fast source of direct heat for manual use, mainly to assist with the removal of seized nuts, bearings, & light preheating jobs. This function provides 1.8kw / 2.7kw output of intense instant heat far hotter than propane or butane torches produce. It’s also a more direct & controllable heat so heats only the item you need heating, the torch cooling air keeps everything else at a low temperature. For instance when removing seized nuts propane torches tend to heat the nut & bolt, Cutmaker plasmas can heat the nut & leave the bolt relatively cool, allowing the nut to be removed quicker. The following are typical times to heat nuts to cherry red. M5 – 3 secs, M6 – 5 secs, M8 – 8 secs, M10 – 14 secs, M12 – 20 secs. In addition, thermal heating function can be used to bend plastic parts or for plastic welding. Thermal heating can be done with cutting consumables fitted for a tight heat focus or gouging parts fitted for a softer wider arc.